Powder coating is an alternative to painting, producing a superior finish in both appearance and durability compared with conventional paints. Powder paints are given an electrostatic charge to make them cling to electrically grounded metal as they are sprayed towards it. The powder is then baked on using regulated ovens in a process known as ‘curing’, which forms a skin as the powder melts and flows. The end result after cooling is a hard-wearing and even polymer coat. The final colour and finish are determined by the choice of powder paint.

Our Process

We have installed a state-of-the-art powder coating plant that has the latest equipment and control systems. Our continuous track and unique parking bays allow for a high throughput by our experienced team of skilled operators.

Pre-treatment

Before powder coating, the removal of dirt, grease and oxides is essential for ensuring the best adhesion of the coating to your metal. Our series of chemical pre-treatment tanks have been designed for this purpose. The appropriate method is selected for each particular job, cleaning and etching the metal as required.

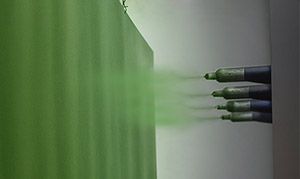

Powder application

The pre-treated metal is loaded onto carrier frames at the start of the track. These frames connect the metal to electrical ground as they pass through the spraying booth. Powder paint is applied using automated and hand-held spray guns that electrostatically charge the powder making it stick to the metal.

Curing

The powder covered metal continues through the regulated convection ovens.

Temperature and timing are carefully controlled so that the powder melts and flows as well as chemically reacts to form a cross-linked polymer film over the surface. After cooling, the final bond achieved between the coating and the metal is very strong.

Care For Your Product

Kestrel Powder Coating is one of the elite companies awarded a QUALICOAT coating applicator approved licence, assuring the quality of its powder coating service for extruded aluminium profiles. QUALICOAT ensures rigorous assessment, with inspectors examining each step of the Kestrel process to ensure that every stage of production and customer service is carried out to consistently high standards.